GASKET INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GASKET INDUSTRIES

Expanded P.T.F.E. Sheet Gaskets And Joint Sealant

We Manufacture Expanded PTFE Gaskets and also Joint Sealants. The high-grade Expanded PTFE Sheet Gaskets is made by special process that produces a uniform and highly fibrillated microstructure.

Attributes

- Can seal uneven damaged flanges

- Resist all chemicals except melted alkali metal, fluorine at liquid and gas states

- Excellent flexibility

- Simple to cut and install

Specifications

- Compressibilty : 66% (ASTM-F36)

- Recovery : 16% (ASTM - F36)

- Material : 100% Pure PTFE, produced in an expanded microporous structure

- Temperature : -240 c to + 270 C (for short bursts + 310.C)

- pH range : 0 - 14 pH except molten alkali metals and elemental fluorin

- Pressure : 3000 PSI (210 BAR)

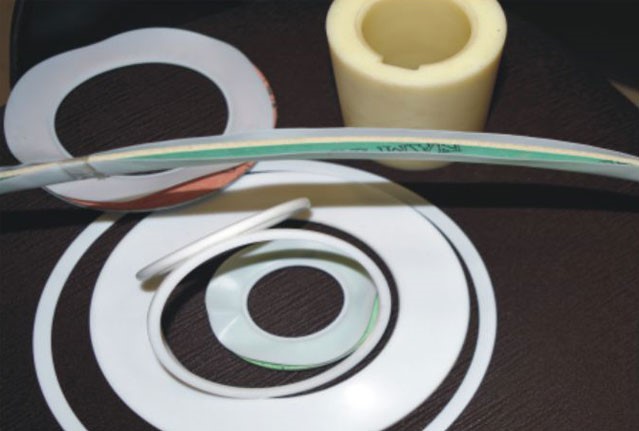

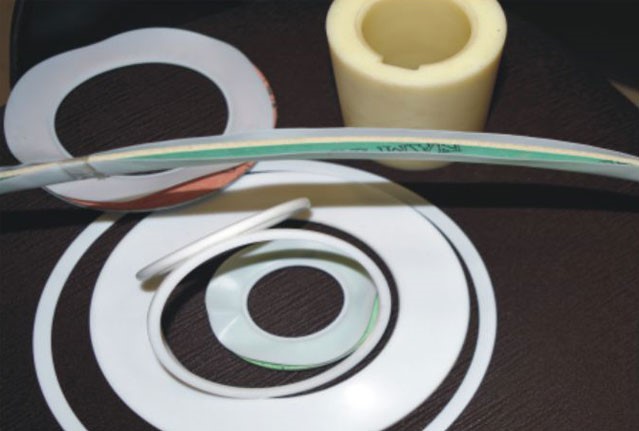

P.T.F.E. Envelope Gaskets Machined Components

Our range of PTFE (Teflon®) Gaskets includes PTFE Envelope Gaskets and Expanded PTFE Sheet Gaskets / Joint Sealants.

Machined components like PTFE 'O' rings , 'T' Bush , seats , seals or as per any special profile / shape to your drawings. Solid PTFE gaskets / Machined components are available in Filled grade as well like Bronze / Carbon / Glass filled PTFE.

PTFE Envelope Gaskets manufactured by us are mainly in two types - Milled type (fused End) and Slit type (Machined). These Gaskets can have Inserts of CAF, Rubber, PVC, Corrugated steel sandwiched between CAF / Non Asbestos rings.

Milled Type - Fused End

It is made to fit the insert and presents a flat face to the flange · Fused End envelopes are being manufactured from Diameters of 400mm to any size with a maximum wall thickness of upto 100mm

Slit Type

These Machined PTFE envelope variant are more suited for smaller diameters and larger quantities. It is perfectly adequate for varied applications.

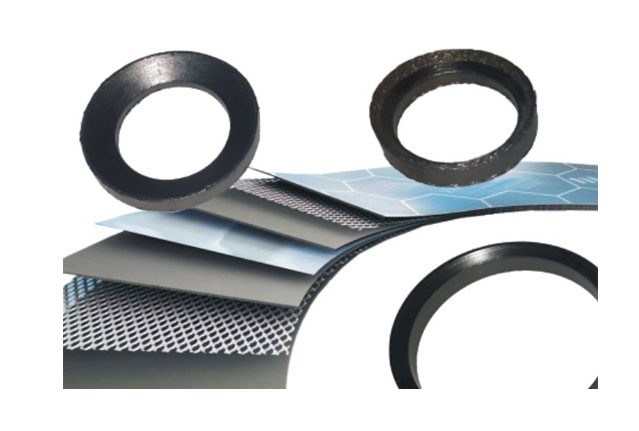

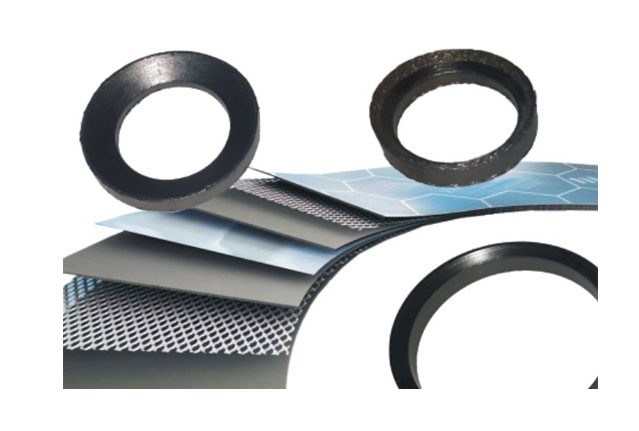

Flexible Graphite Gaskets

Graphite (Graphoil®) moulded Rings are made from pure graphite containing no binder or fillers. Graphite Gaskets can be made to any size, shape, profile as per Drawing from Sheets. These may be from

- Plain Flexible Graphite

- Sheet / Foil insert

- Tanged Sheet insert

- Sheet / Foil insert

- Tanged Sheet insert

- Sheets / Gaskets with Metal insertion of SS 304 / SS 316 / GI

- Wire Mesh in Stainless Steel / Carbon steel.

The Graphite Gaskets are specially designed to provide the desired compression with high percentage recovery and low creep relaxation. Seals the minutest imperfections – Effective and excellent Sealing.

- High Temperature Resistance : -200 deg C to 600 deg C (+3000C in non-oxidizing areas)

- High Chemical Resistance : PH 0-14 · High Pressure Resistance : Upto 1000 PSI

- High Cross Section Density : 1.6 gm/mm (For Moulded Rings) depending on design Upto 12000PSI for metallic Gaskets

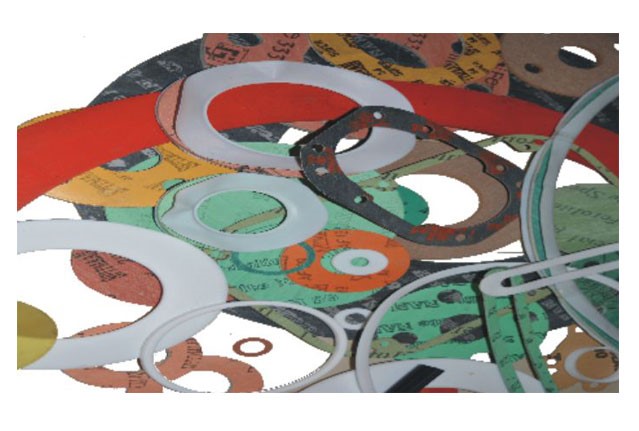

Rubber Gaskets

We manufacture Rubber Gaskets and 'O' Rings from high-grade raw materials in order to give a durable performance. Our Moulded Gaskets and Extruded Rubber Gaskets in different profiles are widely used in various industries and applications. The Rubber Gaskets are available in varied hardness and other physical parameters as per the client's requirements. These may sometimes be reinforced with Fabric insertion of Cotton / Nylon / Metallic wire Mesh / Solid Steel Insert.

Components:

- 'O' Rings

- Washers

- Gaskets for Manhole / Flanges in Full / Flat Face or Raised Face

- Moulded Components

- Extruded Profiles / sections

- Self Adhesive Strip Panel Gasket

- Expansion Bellows

- Hose Pipes

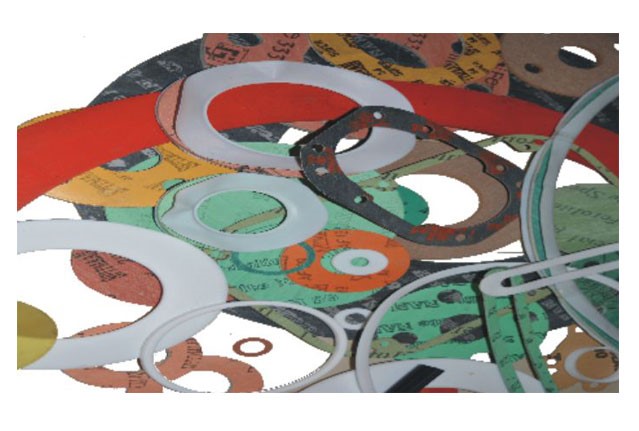

Standard Flange Gaskets

Gaskets as per Sketch/Drawing/Samples/Templates · Standard gaskets for flanges as per ASME B 16.21 (suitable for ANSI B 16.5 flanges ) ; BS 10 table ; DIN gaskets in raised face and Flat / Full face

From all types of materials like· Rubber - Plain / Inserted ( Cotton / Nylon) · CAF (Compressed Asbestos Fibre ) · Flexible Graphite Plain/ Metal Insertion ( Tanged / Reinforced with Wire mesh) · PVC · PTFE · Vegetable Fibre · Rubberised Cork · Ceramic · Shims · EVA / Foam and many others.

Spiral Wound Metallic Gaskets

Our Spiral Wound Metallic Gaskets are skillfully manufactured by spirally winding a preformed metal strip and filler on the outer periphery of metal winding mandrels. Its winding mandrel outside diameter forms the inner diameter of the gasket and the hoop strip continually wounds until the required outer diameter is attained.

We offer Spiral Wound Metallic Gaskets in standards as per ASME B 16.20 suitable for flanges of ANSI B 16.5 , MSSP 44 flanges for SORF , Tongue and Groove .

We manufacture gaskets with Inner and Outer Ring with Partition Ribs for tube vessels, heat exchangers. These can be customized with standard and non-standard thickness and sizes upto 2000 mm Outer Diameter as per the client's requirements.

Flange Insulation Gasket Kit

An effective form of controlling losses due to corrosion. They can be used to control stray electric currents in piping at oil, gas, water, refinery and chemical plants and increase the effectiveness of cathodic protection systems and confine or eliminate electrolytic corrosion. Most common components being a Gasket, Sleeves for bolt protection, and washers for nut protection. The variety of component materials is dependent upon application.

Type “E” gaskets have the same outside diameter as the flange offering full protection. This will prevent the collection of foreign matter between the flange faces and ensures complete cathodic isolation. A wide variety of materials are available to suit the requirements. Type “F” gaskets are made to fit inside the bolt circle and cover the raised face portion. It is recommended that a dirt guard be used to prevent foreign matter from shorting out the flanges. The flanges can also be wrapped. A wide variety of materials are available to suit the requirements. Type “D” or RTJ gaskets are made to fit the ring groove on ring type joint flanges. Usually manufactured from phenolic based materials. Gaskets Type E and F can be manufactured from: · Phenolic (plain and neoprene faced) · GRE (Glass Reinforced Epoxy) · Asbestos sheet gasket · Non Asbestos Material · Special Elastomers .

Compressed Non Asbestos Jointing

We manufacture compressed non asbestos jointing which is gaining significance due to the known hazards of asbestos made products. A wide range of proven compressed non asbestos jointing that covers gaskets with high fluid media in addition to a few special applications. Following are the special features of the compressed non asbestos jointing :

Has high strength and durability.

Up to 450°C working temperature.

Incomparable chemical and steam resistance.

Industrial Cut Gaskets

We manufacture industrial cut gaskets tailored as per the needs and requirements of our customers

Our clients can provide us with the required specification in the form of a drawing standard as per ASA, BS, DIN, etc. They can also detail us with the specifications with regard to size, sample and drawings from any essential gasket material such as CAF, cork, graphoil, oil paper, vegetable fibre, felt, PTFE, rubber and non asbestos sheet.

Graphoil Ring Gaskets

Graphoil (flexible graphite) compression moulded ring gaskets are able to withstand very good temperature resistance: (-) 200 deg C to 600 deg C (+ 3000 deg C in non oxidising temp) and High pressure up to 10000 PSI (and up to 12000 PSI with metallic reinforcement). Graphoil ring gaskets are manufactured from 100% graphite which does not contain any binder or fillers. They have good Chemical Resistance – PH 0-14

These gaskets rings have.

- No Thermal Expansion / Ageing

- Self Lubrication and are Non Corrosive and Non abrasive

Ring Joint Gaskets

Ring joint gaskets are manufactured in different solid metal types such as Soft iron/SS304/316/321 metals and similar other alloys. These ring joint gaskets are ideal for the industrial use due to their enhanced performance and reliable durability. These ring joint gaskets stop leakage that causes corrosion around manholes and hand holes in steam boilers, water heaters and air tanks.

The RTJ rings are in profiles of R, Rx and Bx series as per std API 6A.

Expanded P.T.F.E. Gaskets

We manufacture Expanded PTFE gaskets from Expanded PTFE sheets, which are made by using special process that produces a uniform & highly fibrillated micro structure with a fibres running in multi directional strength. The lubricity creep & cold flow directs the possibility of blow out. Salient Features :

- Can seal uneven damaged flanges.

- Resist all chemicals except melted alkali metal, fluorine at liquid and gas states.

- Good flexibility

- Compressibilty-66% (ASTM-F36)

- Recovery - 16% (ASTM - F36)

- Easy to cut and install

- Material: 100% Pure PTFE, produced in an expanded microporous structure.

- Temperature : -240 c to + 270 C (for short bursts + 310.C)

- pH range : 0 - 14 pH except molten alkali metals and elemental fluorine

- Pressure : 3000 PSI (210 BAR)

P.T.F.E. Sheet Gaskets

- PTFE machined components – Solid – Virgin / Carbon Filled / Glass Filled

- PTFE Envelope – Mill / Slit type and Fused end with large diameters ( Any size and Urgent deliveries) with insert options of Rubber / Non Asbestos with SS corrugated rings

- PTFE ‘O’ , ‘ D ’ Rings for Chemical machinery / equipments

- 0% coefficient of Friction

- Pressure up to 3000 PSI (210 Bar) and temperature up to 260 deg C

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.